At more3D, we’re excited to celebrate the success of our first joint project with Feynsinn, eine Marke der EDAG for a mechanical and plant engineering company. Feynsinn experts in consulting and supporting midsized companies in digitalization, especially in digital twins and virtual commissioning, for over 10 years. This collaboration has proven how real-time VR solutions can enhance industrial workflows, making complex processes more efficient and accessible.

Q: How does this partnership benefit customers?

Feynsinn: “The combination of our expertise in digital engineering with strong consulting focus and more3D’s real-timeVR technology is key. Our collaboration was also highly flexible, even when working on short notice or late hours. more3D values feedback and actively integrates it, making the partnership dynamic and continuously improving.

“more3D values feedback and actively integrates it, making the partnership dynamic and continuously improving.”

Lastly, every customer has unique needs, and many companies offer only standardized solutions. more3D, however, goes the extra mile and is technology-open, adapting to customer-specific requirements, aligning with our own mission at Feynsinn.”

Q: What benefits did VR bring to the last project?

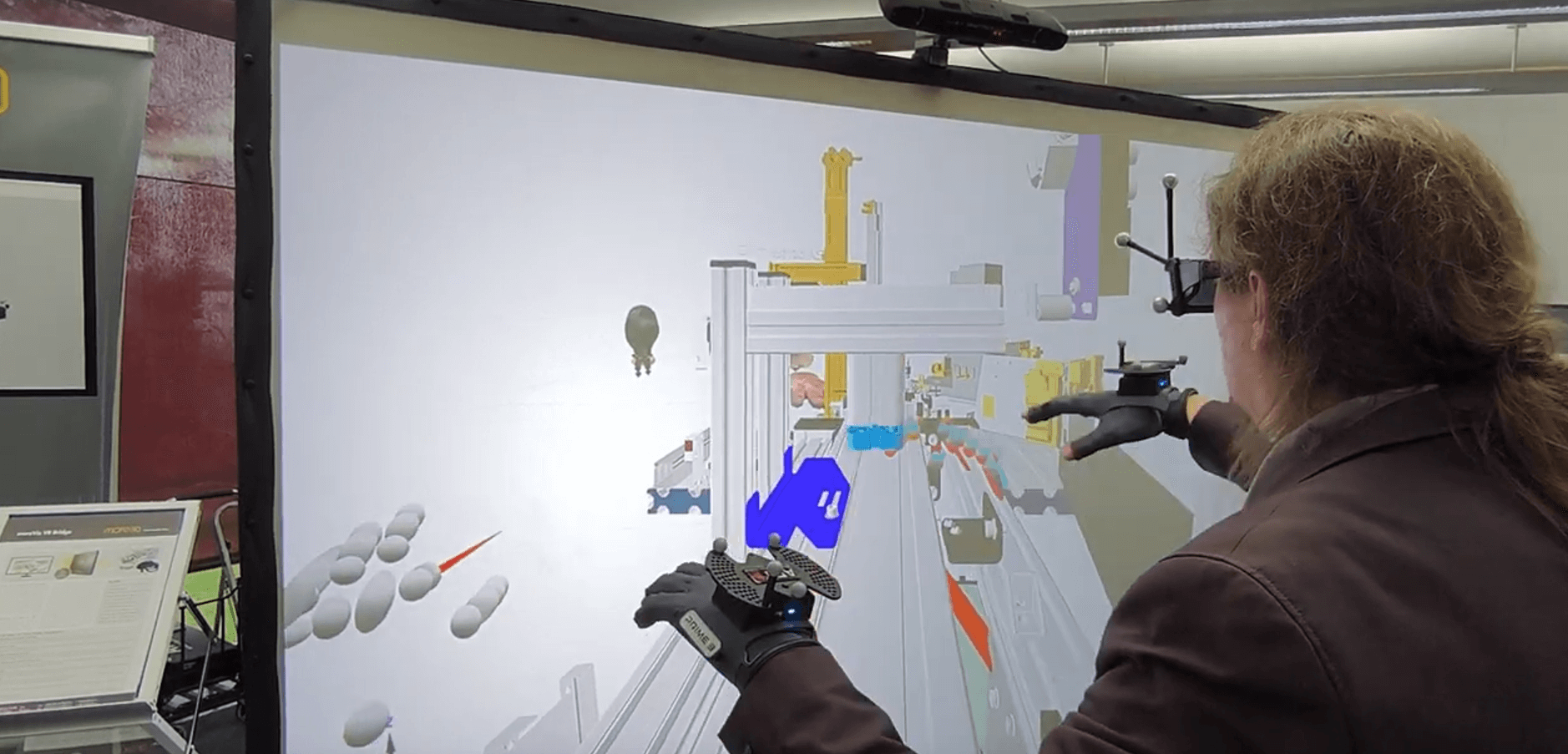

Feynsinn: In this project, we worked with a 500-meter-long machine, which could never be realistically displayed on conventional monitors. But with Virtual Reality, engineers could explore production setups, adjust layouts, and simulate automation processes in real-time.

Automation engineers could work inside a virtual machine instead of relying on 2D screens or walking across massive factory floors with laptops. They had the machine “next to them” in the office, instantly teleporting from one point to another, significantly improving workflow efficiency.

Sales teams also benefited—what used to be static 3D models became highly immersive, near-real experiences for clients.

Q: What made more3D’s technology stand out for you?

Feynsinn: more3D excels in three key areas:

- Instant CAD Integration – Normally, preparing CAD data for VR occupies a lot of resources—but with more3D’s CAD plug-in, it’s instant – without additional preparation. This allowed us to present and refine concepts much faster, making VR a practical tool for real working environments.

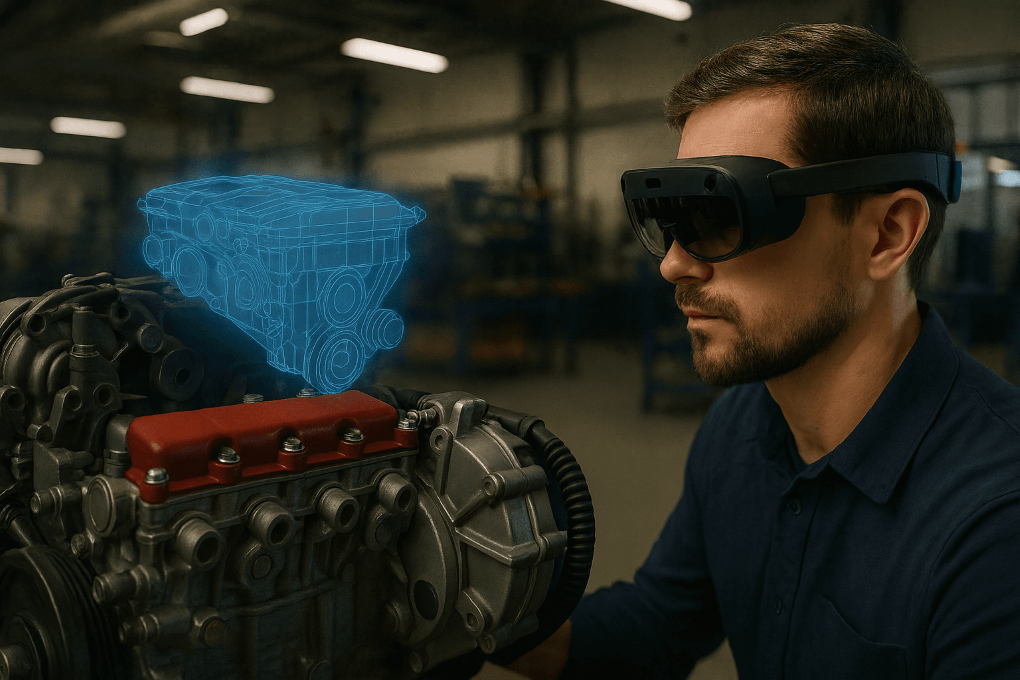

- Hardware Flexibility – Compatible with nearly any head-mounted display, making it highly adaptable.

- Cost-Efficiency – Many VR solutions are complex and expensive — but more3D delivers a professional, accessible, cost-effective solution.

“Many VR solutions are complex and expensive — but more3D delivers a professional, accessible, cost-effective solution.“

Q: Where is VR & AR headed in the next 3-5 years?

Feynsinn: A few years ago, VR was hyped, but technology wasn’t advanced enough for companies to fully integrate it. That early disappointment still lingers—but things have changed drastically.

Today, VR is a practical tool for engineering, design, maintenance, and marketing. The pace of development is accelerating, and within 3-5 years, VR will be a standard tool in industrial environments.

It won’t replace traditional work entirely, but VR-equipped workspaces will become common, enhancing how engineers and designers collaborate. Companies that adopt VR early will gain a major competitive advantage, streamlining processes and improving decision-making.

“Companies that adopt VR early will gain a major competitive advantage, streamlining processes and improving decision-making.”

Curious about how VR can give your business an advantage?

Let’s explore the possibilities together. Request a free demonstration from more3D and Feynsinn a brand of EADG PS and see the benefits for yourself!