A New Chapter in Engineering Education with a VR CAVE

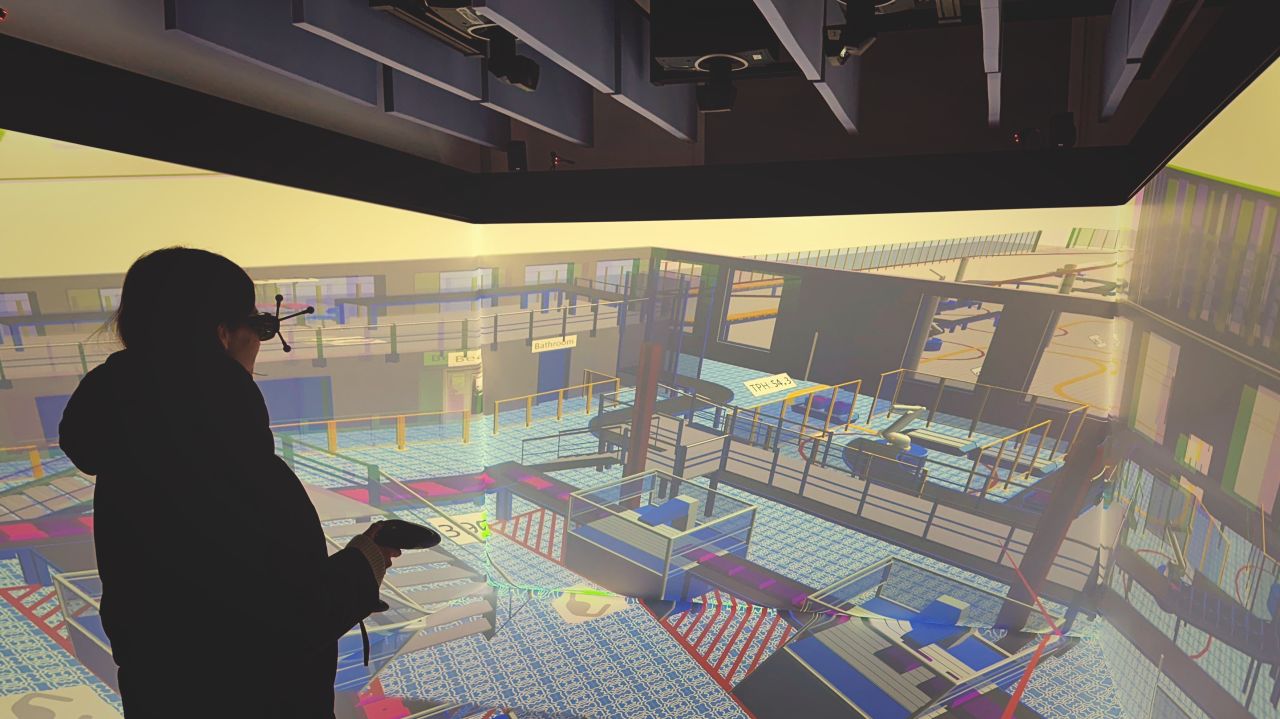

As Industry 4.0 and digital twin technologies reshape engineering workflows, immersive visualization is becoming an increasingly important part of both academic training and applied research. At Hochschule Zittau/Görlitz, a new VR CAVE — developed in collaboration with IMSYS and more3D GmbH & Co. KG — brings these concepts to life in a practical, hands-on learning environment.

The system is still in its early stages of use, but the planning, implementation, and first applications already offer meaningful insights for other institutions pursuing similar goals.

From Concept to Collaboration

The idea for the CAVE emerged two years ago, when Hochschule Zittau/Görlitz approached more3D regarding a VR software bridge for their engineering tools — and simultaneously contacted Imsys to explore hardware options. While immersive technology was already of interest at the university, 3D monitors had proven limited — especially in terms of spatial perception and collaborative use.

Imsys developed the technical concept for the CAVE environment, while more3D provided the software foundation with moreViz. A key requirement was integration with Festo‘s automation tools, which were not initially supported by moreViz. more3D responded quickly by customizing the software to handle Festo data natively — allowing the university to keep its existing workflows and benefit from immersive visualization.

“There was no FESTO interface at the time,” explains Prof. Dr.-Ing. Knut Meissner Knut Meißner. “But more3D adapted moreViz to meet our requirements — that flexibility made a huge difference.”

Use Cases and Educational Goals

At Hochschule Zittau/Görlitz, the VR CAVE is already embedded in both teaching and research. It plays a key role in preparing students for future careers — where immersive tools and digital twins are becoming increasingly common.

Use cases include:

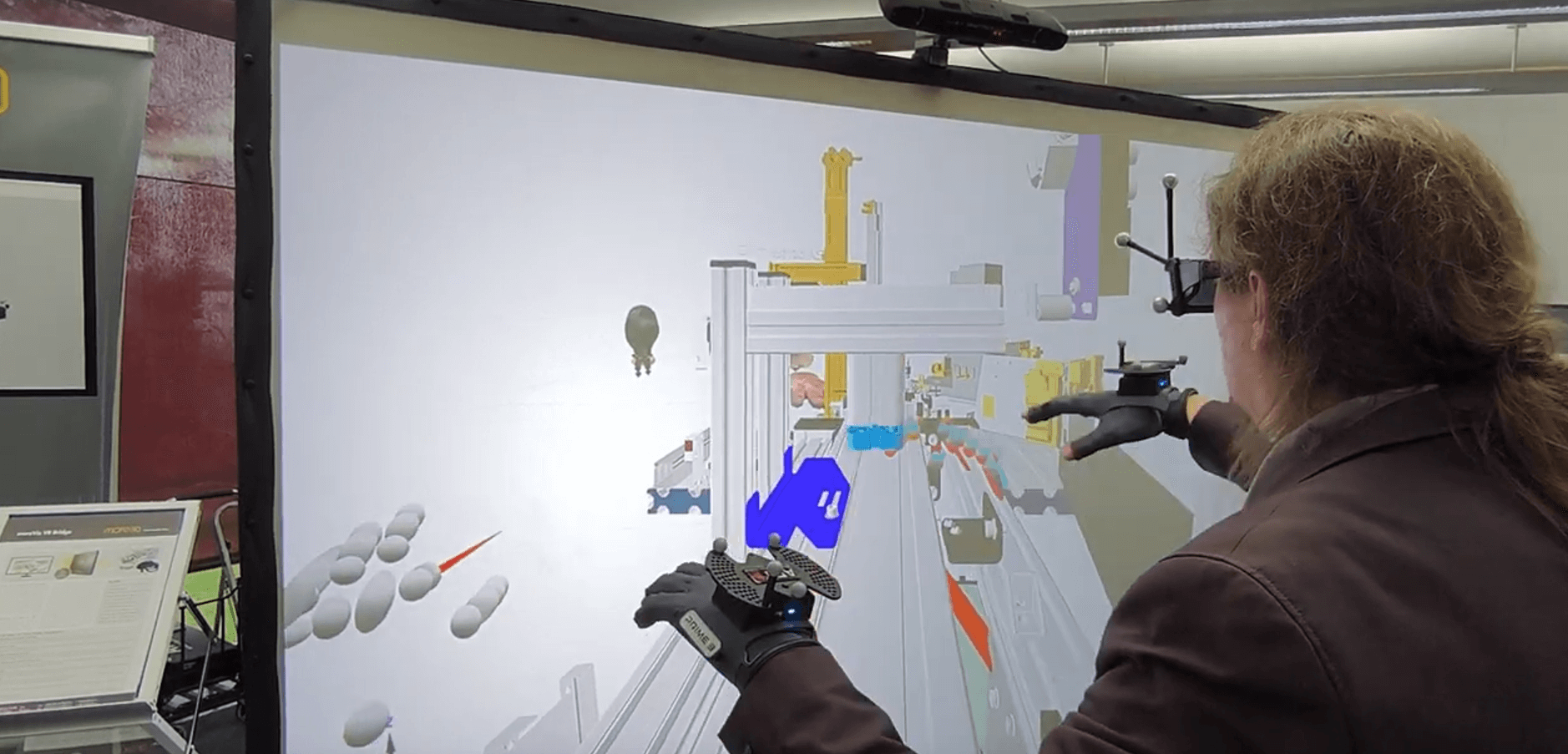

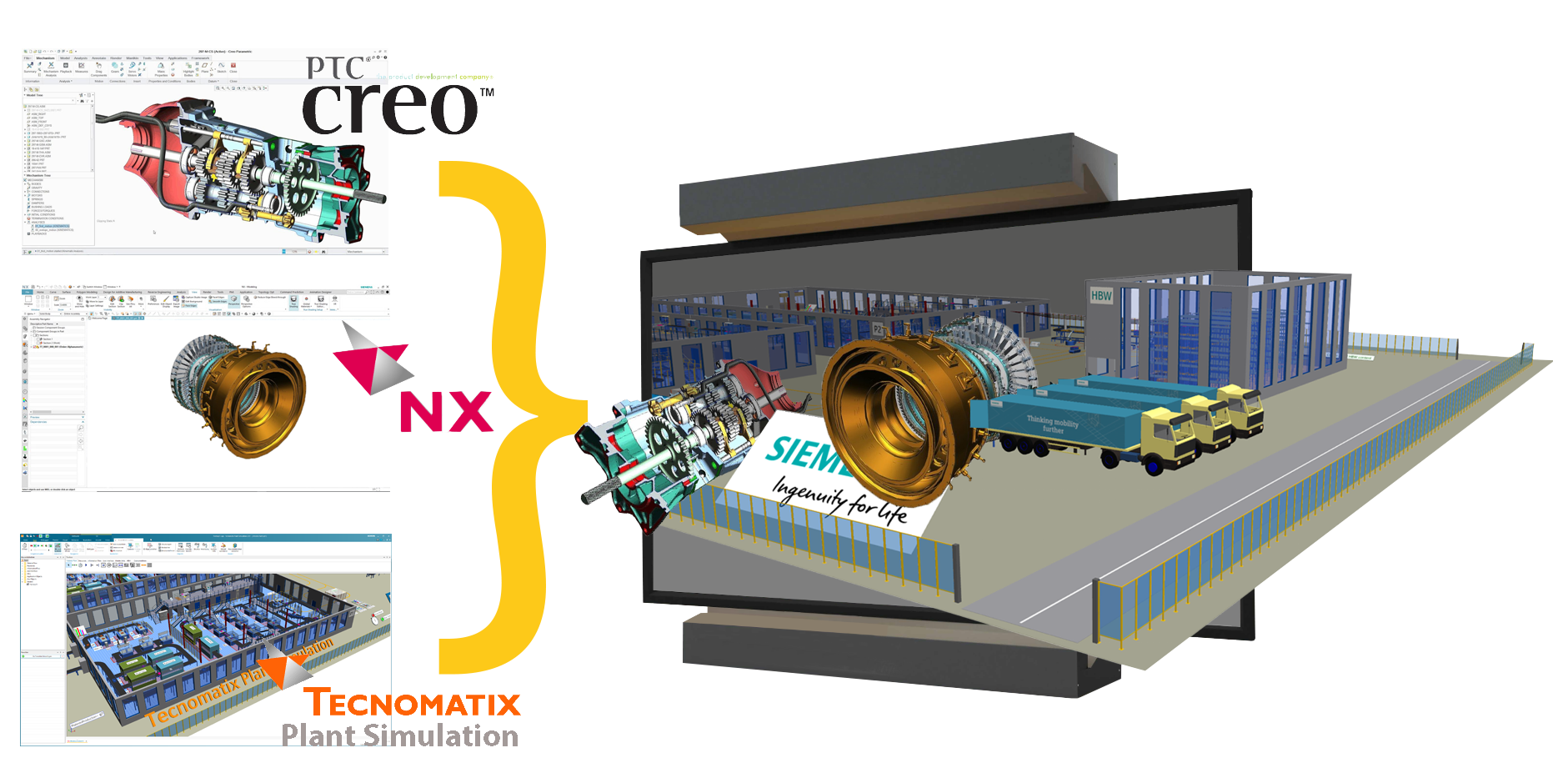

- Immersive visualization of digital twins and using Siemens NX, PlantSimulation, SolidEdge, JT2Go, SAP Visual Enterprise and FESTO

- Virtual plant engineering and layout prototyping

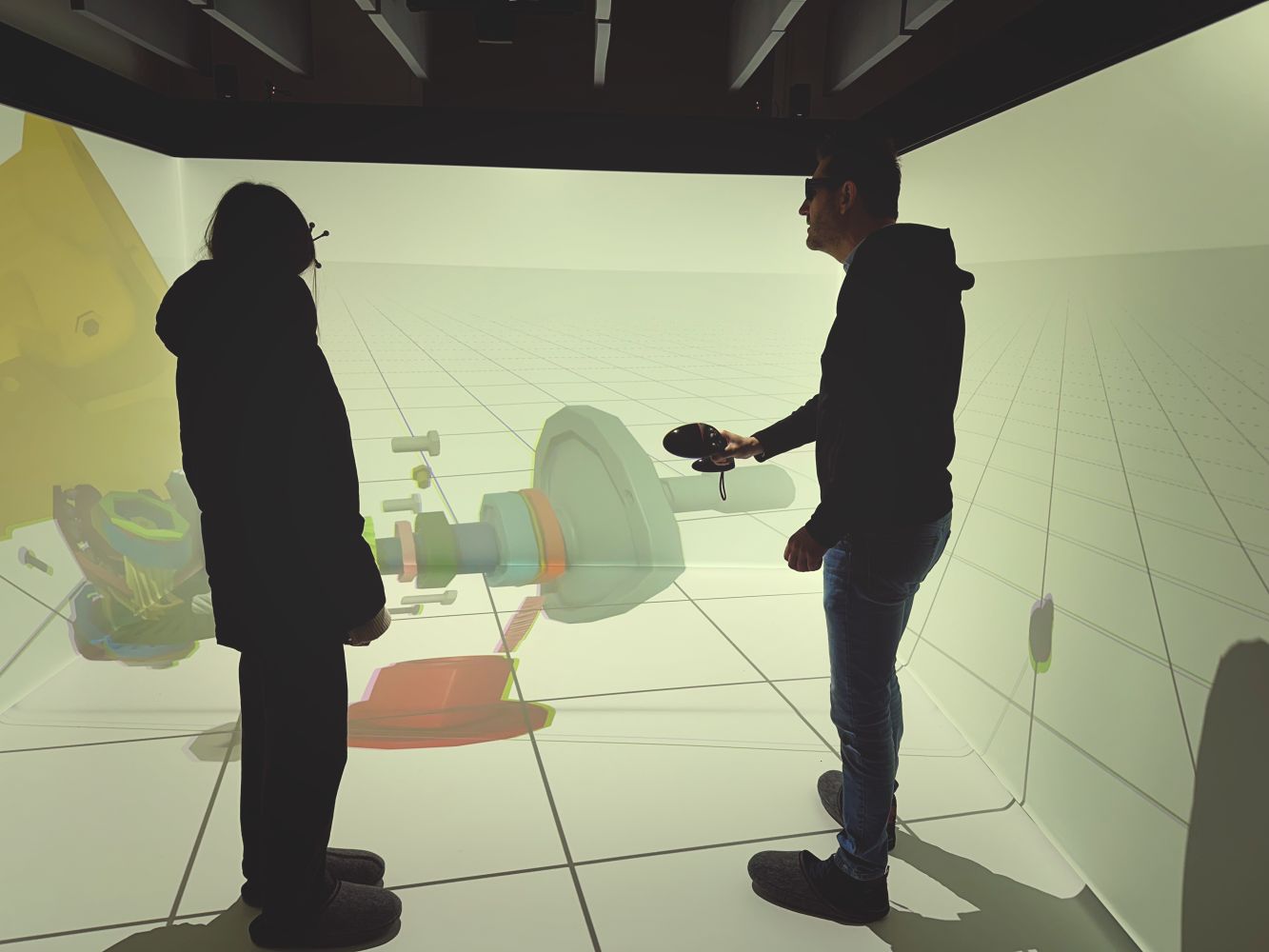

- Usability and ergonomic evaluations of industrial equipment and consumer products

- Simulation-based training and maintenance planning

- Cross-site collaboration — including live immersive sessions with partners in Shanghai, allowing distributed teams to inspect and discuss the same virtual models in real time

- Practical training for students, helping them develop experience with VR tools used in modern industry

“With the CAVE, we can walk through and discuss complex systems together,” says Prof. Meißner. “Students don’t just observe — they participate, and that experience is critical as VR becomes more relevant in engineering practice.”

Rather than replacing desktop engineering, the CAVE enhances existing workflows — particularly for:

- Ergonomic studies

- Collaborative review and decision-making

- Communicating design intent across teams and borders

Technical Setup and Timeline

The CAVE system was fully designed and built by Imsys, using a precise and robust setup tailored to the space available.

Technical specifications:

- Image dimensions: 3.36 × 3.36 × 2.1 m

- Projection: Rear projection with five Barco projector on four fixed dry walls for seamless, distortion-free imaging and Advanced Realtime Tracking GmbH & Co. KG infrared tracking

- Rendering architecture: One dedicated server per projector, housed in a separate cluster room and connected via fiber optics

- Structural concept: Solid dry-wall construction to minimize vibrations, eliminate screen deformation, and simplify installation

- Software VR Bridge: moreViz by more3D, allowing seamless transition of data in the CAVE without converting.

Project Implementation:

- CAVE assembly: around 2 weeks

- Room preparation (e.g., structural modifications, climate control): several months

- Total investment: approx. €500,000

Lessons Learned

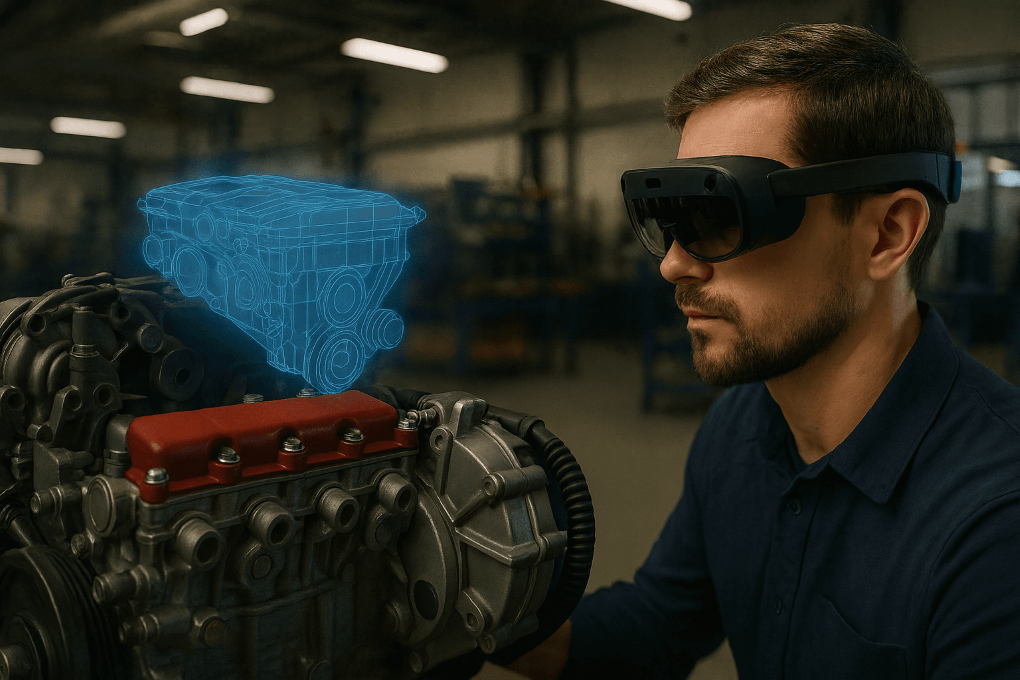

1. Start small and build with insight Begin with VR head mounted displays (HMD) to gain internal knowledge and understand where immersive workflows offer real value. This foundation helps define goals before scaling up to a full CAVE.

2. Assign ownership A system like this requires someone on-site who understands it, supports users, and ensures it’s actively integrated into coursework and research.

3. Design within your constraints Rather than designing a building around the CAVE, the team worked with the existing room. Imsys’s dry-wall projection setup offered a reliable providing a vibration-free, sealed structure — eliminating screen deformation and reducing the impact of external movement or airflow

4. Plan for dependencies While the CAVE itself was built in two weeks, delays with the external climate system provider added months. It’s critical to anticipate such logistical dependencies in project timelines.

5. Choose partners who adapt The integration of Festo into moreViz was not initially available — but more3D responded quickly and effectively. Their ability to tailor the software to project needs was essential.

Partner Profiles

Hochschule Zittau/Görlitz A university of applied sciences in Saxony, Germany, focused on engineering, technology, and cross-disciplinary education. The university emphasizes hands-on learning and international cooperation, preparing students for real-world challenges — including working with modern VR tools and digital twins.

Imsys A German specialist in visualization technology and system integration. Imsys planned and implemented the full media solution for the CAVE, including projection, room integration, distributed rendering architecture and management software.

more3D Developer of moreViz, a software bridge that enables real-time visualization of 3D CAD and simulation data in VR environments.

“The result isn’t just a system,” says the project team. “It’s a fully functional environment where students, researchers, and partners can work together — in real scale and real time.”

Conclusion: What Collaboration Makes Possible

The VR CAVE at Hochschule Zittau/Görlitz demonstrates what’s possible when clear goals, capable technology, and committed partners come together.

By starting with a real need — immersive digital twin visualization — and building around that vision, the university created a powerful platform for teaching, research, and collaboration. It’s a space where students gain hands-on experience with the tools of tomorrow, and where international teams can meet inside the same virtual model.

If you’re exploring similar solutions or would like to see the system in action, we’d be happy to provide more information or arrange a demonstration. Whether you’re interested in the technical setup, educational use cases, or software integration, feel free to reach out — we’re always open to sharing insights and experiences.

You may also like:

VR in Architecture: How Immersive Tech Is Revolutionizing Design & Project Delivery

Architecture is often about translating vision into built reality—but that translation has traditionally been messy. Clients imagine, architects render, models are built—and misalignments, miscommunications, and

How Precise Motion Tracking Shapes the Future of Industrial VR

An Interview with Ulrich Probost , CEO of ART (Advanced Realtime Tracking GmbH & Co. KG) In professional VR and XR environments, the accuracy

Hands That Shape the Future: An Interview with MANUS

When we think about Virtual Reality, visuals and sound usually come first. But what about our hands—the most natural tool we have for interacting with

Passthrough Mode vs. Augmented Reality (AR): What’s the Difference and What’s Best for Your Business?

Immersive technology is reshaping the way companies design, train, and collaborate. But with so many buzzwords — AR, VR, MR, Passthrough — it can be

Work Smarter in VR: Unlock the Power of Composition Mode

Composition Mode in moreViz: Bringing All Your Tools into One VR Workspace In engineering, manufacturing, and product development, teams often work across multiple software environments.

Which VR Head-Mounted Display (HMD) Is Best for Your CAD Workflow?

The Best VR Headsets for CAD Professionals: How to Choose the Right HMD Bringing your CAD models into Virtual Reality is no longer a novelty