Immersive technology is reshaping the way companies design, train, and collaborate. But with so many buzzwords — AR, VR, MR, Passthrough — it can be hard to know what actually matters for your business.

Here’s the question decision-makers are really asking:

Which technology will make my workflows faster, safer, and more efficient?

Let’s break down Passthrough Mode and Augmented Reality (AR), explain their differences, and show why Passthrough is becoming the go-to solution for professional workflows.

🔍 Passthrough Mode Explained

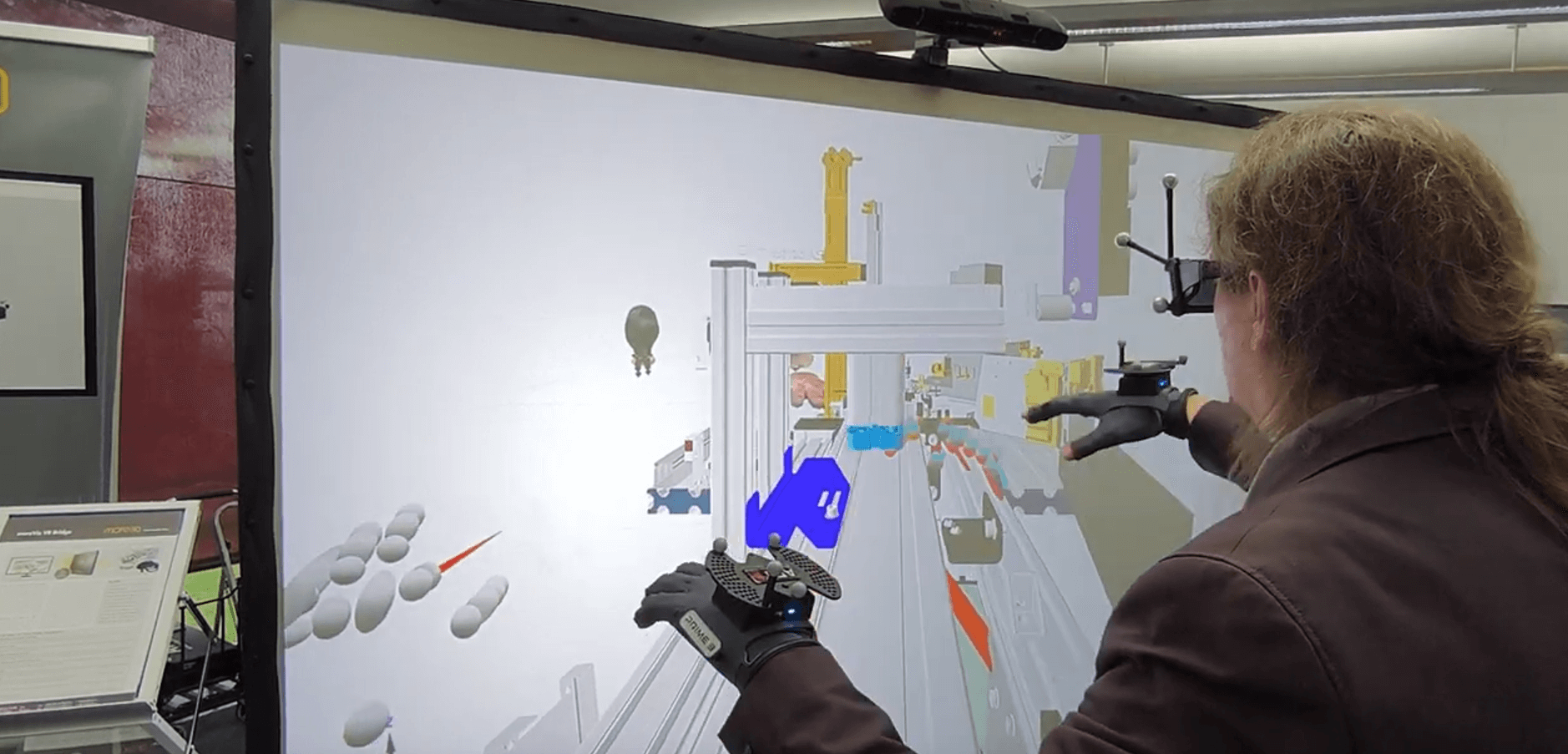

Passthrough Mode uses high-resolution cameras on a VR headset to show you your real surroundings inside the headset. Instead of being fully cut off from the real world, you see a live, full-color feed — with virtual content layered on top.

Modern devices like Meta Quest 3 and Varjo XR-4 offer sharp, low-latency Passthrough that feels natural enough for serious work. This transforms a VR headset into a mixed-reality workspace, perfect for teams who need immersion and awareness of their physical environment.

✅ Where Passthrough Shines

3D Design & CAD Reviews

Step inside your models, walk around full-scale prototypes, and catch design flaws before anything is manufactured.

Collaborative Reviews & Meetings

Run immersive design reviews with remote teams. Everyone stays grounded in their real offices but shares the same interactive space.

Mixed-Reality Training

Combine real-world equipment with virtual scenarios so employees can practice safely and confidently.

⚠️ Things to Consider

Passthrough quality is excellent, but still not identical to natural vision.

Headsets are heavier than AR glasses — plan sessions with comfort breaks.

Good lighting helps maintain image clarity since Passthrough relies on cameras.

🔍 AR Explained

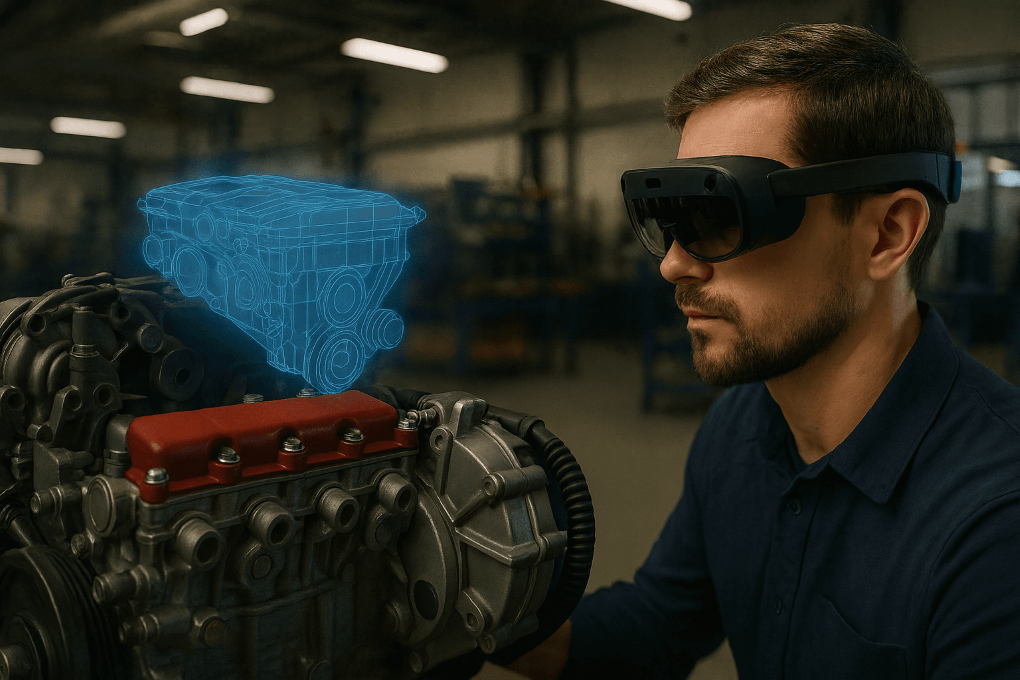

Augmented Reality overlays digital content directly onto your natural vision through transparent lenses — no camera feed required. You see the real world naturally, with virtual instructions, data, or graphics layered in.

This makes AR especially useful for hands-free, mobile workflows in logistics, maintenance, or field operations.

✅ Where AR Excels

Hands-Free Guidance: Display assembly steps or diagnostics right in the user’s line of sight.

On-Site Data: Show machine data, inventory status, or alerts directly in context.

Field Work: Lightweight glasses are perfect for mobile workers across large sites.

⚠️ AR Limitations

Smaller field of view can make content harder to see at a glance.

Not immersive enough for spatial reviews like product prototyping or layout planning.

Hardware and integration costs are often higher than VR headsets.

🎯 Why Passthrough Is Leading in Enterprise

For manufacturing, engineering, and training teams, Passthrough Mode is often the most practical first step into XR:

Deep immersion for design reviews, simulations, and planning

Real-world awareness for safety and collaboration

Affordable devices like Quest 3 or Pico 4E — no need for ultra-expensive hardware

At more3D, we help teams use Passthrough to:

Visualize full-scale layouts without moving a single machine

Train employees in safe, realistic scenarios

Enable global collaboration in shared virtual workspaces

🚀 Choosing the Right Technology

For design-heavy, process-driven industries, Passthrough Mode offers the best balance of immersion, safety, and cost-efficiency.

AR still has an edge for mobile, hands-free workflows — but if your goal is collaborative design review, simulation, or immersive training, Passthrough is the clear winner.

Ready to See Passthrough in Action?

💡 Watch our demo to see a full-scale factory placed in any room.

📩 Contact us to explore how Passthrough can transform your design, training, and production workflows.