An Interview with Ulrich Probost , CEO of ART (Advanced Realtime Tracking GmbH & Co. KG)

In professional VR and XR environments, the accuracy of motion tracking determines whether a system truly works. For engineers, researchers, and educators, reliable tracking transforms virtual concepts into measurable, reproducible results.

Few companies understand this better than ART, a German pioneer in optical motion-tracking technology. For over 25 years, ART has developed and manufactured camera-based localization systems used in CAVEs, Powerwalls, simulators, and mixed-reality laboratories worldwide. Their expertise has made them one of the most trusted names in precision, robustness, and long-term system stability.

“Reliable tracking is what turns immersive visualization into a dependable engineering tool.”

In this interview, Ulrich Probost, CEO of ART, discusses the engineering principles behind optical tracking and offers insights into how reliable tracking enhances ROI, user comfort, and data integrity in professional VR applications.

What Makes ART Unique in the VR Landscape?

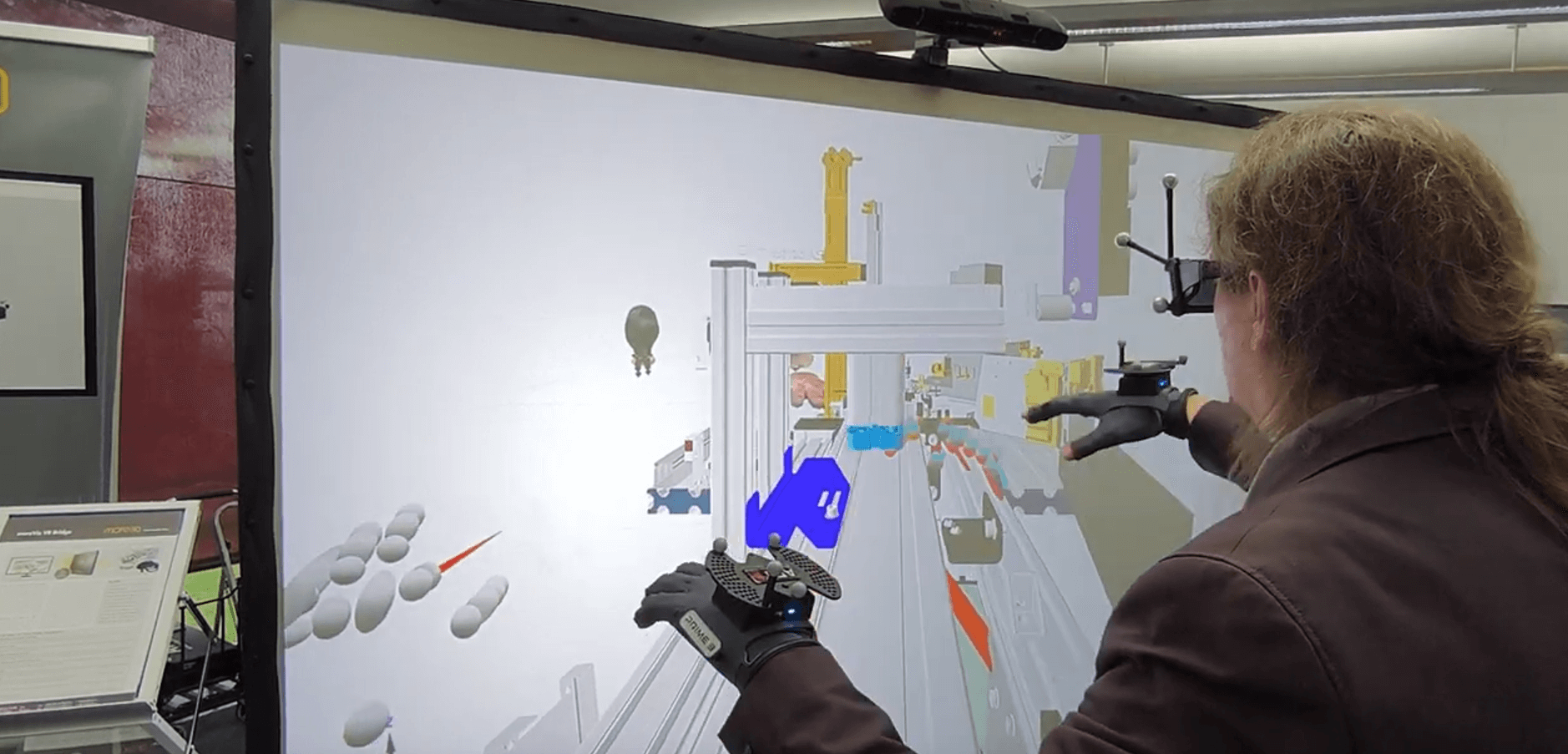

Responding to the growing demand for precise tool tracking and optimized production workflows, ART developed a camera-based localization system that detects errors and irregularities throughout manufacturing. Operating in an environment of expert partners providing turnkey VR and AR solutions, ART focuses on delivering systems that — though complex to plan and install — are simple and intuitive in daily use.

The company’s strength lies in its exceptionally accurate and stable infrared-tracking technology, designed for demanding use cases such as multi-view stereo setups, drone and robot tracking, driver-monitoring systems, and flight simulations.

Every component is engineered and produced in Weilheim, south of Munich, where all departments work under one roof — ensuring tight quality control and rapid response to custom requirements.

How Does the Engineering Behind Reliable Tracking Work?

High-end tracking demands technology that delivers extremely accurate results in real time. Infrared motion tracking depends on sub-millimeter precision, minimal jitter, and low latency.

ART’s systems are engineered to maintain these parameters consistently over years of operation, embodying the core principles of German mechanical and optical engineering.

Which Industries Benefit Most from VR?

The automotive industry was first to adopt ART’s technology, replacing physical prototypes with digital twins. This shift enabled faster design iterations, global collaboration, and a measurable reduction in material waste.

Since then, aerospace, construction, and manufacturing sectors — as well as marketing, training, and simulation — have embraced the same precision to accelerate development cycles and manage the growing complexity of global production chains.

What Does more3D Bring to the Collaboration?

From the beginning, more3D has been a reliable and valuable partner — highly skilled, knowledgeable, and open to new ideas. Its platform moreViz allows multiple software solutions to operate seamlessly within one VR environment.

“Together, we deliver complete, user-friendly systems where motion tracking functions as the invisible backbone.”

With deep market insight, an extensive network, and a broad range of VR solutions, more3D consistently contributes to systems that combine technical excellence with everyday usability.

Example of moreViz realtime Virtual Reality Bridge with MANUS™ Gloves and ART on Powerwall

What Real-World Applications Have You Seen?

Industrial adoption of head-mounted displays (HMDs) has surged. Companies now expect real-time precision without motion sickness or drift, even in confined spaces.

ART provides the necessary stability across small and large tracking volumes alike, supporting advanced connectivity with leading HMDs.

One memorable project involved drone tracking within a large environment, testing how accurately a drone could be localized across a wide area. The testing process was both successful and a lot of fun.

In research, ART collaborates with Technische Universität Berlin on the KamIn GFK project, which explores robot control via trajectory planning supported by external tracking data, funded by the Bundesministerium für Wirtschaft und Energie.

Other Notable Industry Examples

BMW M Group – Mixed Reality Project Using SMARTTRACK 3, BMW M created a mixed-reality driving experience merging real and virtual racing — demonstrating how precise tracking enables seamless synchronization between physical and digital motion. (BMW M Mixed Reality on LinkedIn)

- Renault Group – Design in Large Spaces ART tracking supports Renault’s collaborative design workflows and was featured in “Renault Design develops Twingo in less than two years, thanks to AI.”

What Do Users Usually Say?

“Once calibrated, it runs forever.”

Users consistently praise the accuracy, stability, and robustness of ART’s tracking systems. This reliability saves time, money — and nerves. Tracking should operate silently in the background — if you notice it, something isn’t right.

How Do You See the Future of VR in Professional Workflows?

VR will remain — and even grow — as an integral part of professional workflows where spatial understanding and collaboration enhance productivity.

In architecture, engineering, and design, professionals already visualize and manipulate 3D models in real time, reducing the need for physical prototypes. Beyond technical fields, VR will transform remote collaboration.

“Instead of flat video calls, teams will meet in immersive virtual spaces that enable natural communication and stronger cohesion — almost like being in the same room.”

Training and onboarding will also benefit, allowing realistic simulations of complex or hazardous environments without real-world risk.

To achieve mainstream adoption, improvements in headset comfort and software interoperability remain essential — but the direction is unmistakable: VR is evolving from an experimental tool to an everyday instrument.

Where Is ART Heading?

At ART, we’re continuously pushing the boundaries of what’s possible in VR, AR, and XR applications. Our commitment is to provide high-quality professional tracking solutions while keeping adaptability and usability at the core.

Current Focus Areas

Expanded versatility: Tracking that scales from compact environments like vehicle cabins to large HMD arenas.

DTRACK 4 software: Streamlining workflows and establishing tracking as an everyday working tool.

AT7-50 camera: Compact, high-performance system with an excellent price-to-performance ratio — ideal for Powerwalls, CAVEs, and multi-user spaces.

Hybrid tracking: Integration of optical and tool-tracking technologies for higher precision and flexibility in industrial and training contexts.

Sustainability plays an increasing role: ART systems replace physical prototypes with high-fidelity virtual simulations, reducing costs, shortening development time, and lowering environmental impact.

In short, ART’s innovations aim to make development smarter, faster, and greener, helping industries meet both operational and sustainability goals.

What Advice Would You Give to Universities and Companies Considering VR?

Universities and companies face growing financial pressure. To avoid costly trial-and-error approaches, Probost recommends adopting industry standards from the start and investing in proven, reliable systems.

“ART systems provide measurable ROI over many years — often decades.”

Closing Thoughts

In a field defined by rapid innovation, ART stands for the engineering fundamentals that make immersive technology dependable: precision, reliability, and endurance.

Together with more3D, the company transforms sophisticated tracking technology into intuitive, stable VR environments for research, engineering, and education.

“When tracking becomes invisible, immersion becomes real.”

Want to Learn More?

Discover how ART and more3D enable realistic, reliable, and collaborative VR experiences for your organization. 👉 Request a free trial or contact info@more3d.com for more information.