How the Berliner Hochschule für Technik uses virtual reality to complement teaching, enhance research, and open new space for interdisciplinary collaboration. (Reading time: 6 minutes)

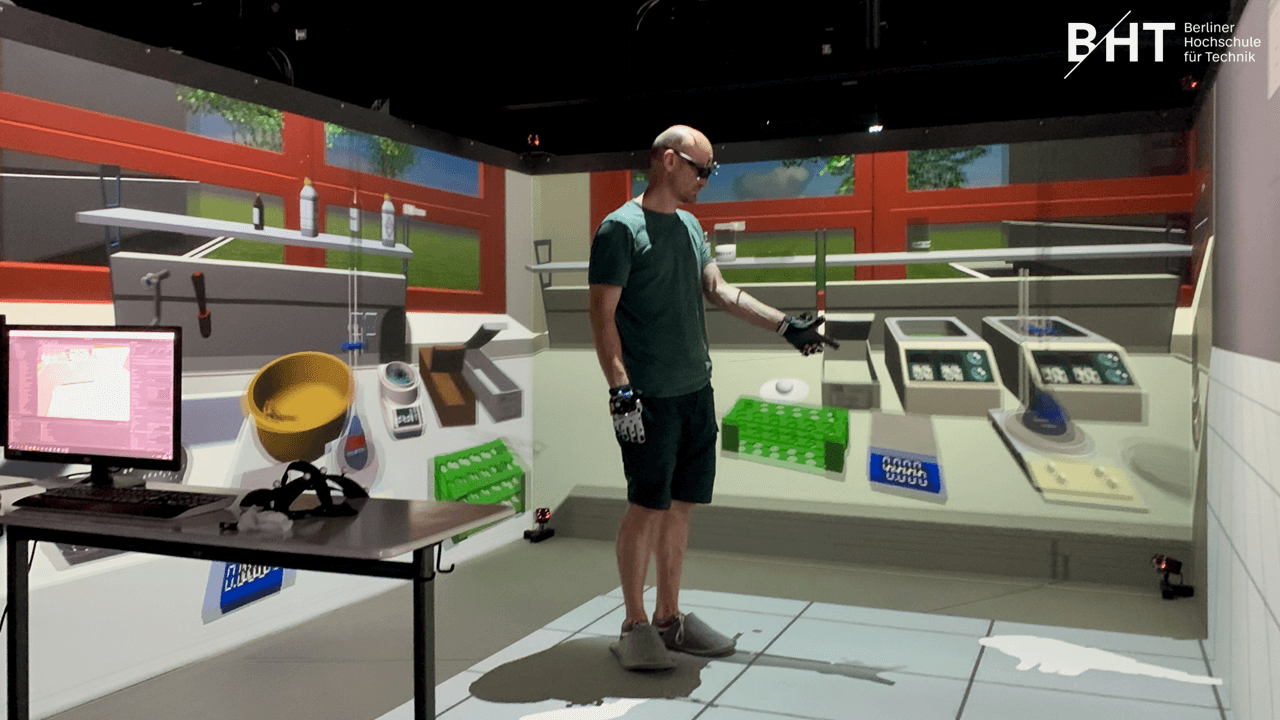

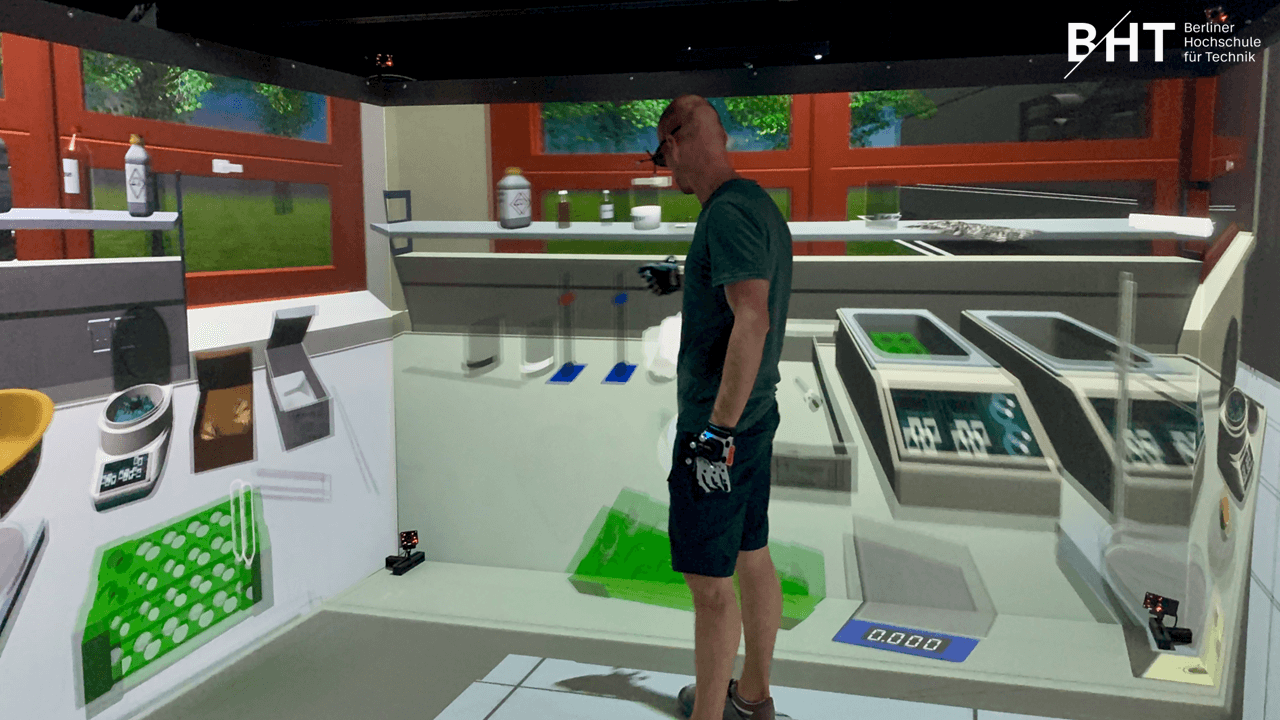

In the heart of Berlin’s Wedding district, the Berliner Hochschule für Technik (BHT) together with WE are XR GmbH and more3D GmbH & Co. KG has created something quietly impactful: a four-sided CAVE (Cave Automatic Virtual Environment with 3 walls and floor projection), where students and researchers step into virtual spaces to plan factories, inspect gearboxes, or—occasionally—simulate the process of producing mozzarella cheese.

At first glance, the setup looks futuristic. Yet its use is grounded in very practical goals: to support hands-on education in engineering, make time-consuming or hazardous experiments more accessible, and enable meaningful collaboration across disciplines.

We spoke with Philippe W., engineer and laboratory staff member at BHT, who has overseen the system’s use and evolution since 2017.

From Mechanical Labs to Digital Twins

The CAVE is anchored in the CAE and Simulation Lab, which serves students in mechanical engineering, process engineering, and event technology. Over time, it has become a hub for broader research — especially under the MINT-VR-Labs project, part of a national effort to promote STEM education in Germany (MINT stands for Mathematics, Informatics, Nature Sciences and Technology).

One core idea of the project is to use VR to support and complement traditional teaching. CAD models and simulation results can be experienced virtually in the CAVE. This offers a different and, for some students, more intuitive way of understanding. This also applies to simulations of biotechnological lab experiments that are otherwise difficult to conduct during regular class hours—like the mozzarella-making experiment. “Normally, the process is too lengthy or complex for a standard lab schedule and therefore be canceled,” says Wesberg. “With VR, students can run through the process and focus on the principles.” In addition it saves quite some time in preparing for the experiment, using the needed resources and cleaning everything up afterwards.

More importantly, the CAVE enables testing of concepts that would be difficult to explore in physical environments. A standout example: a virtual barrier-free factory, allowing detailed analysis of accessibility, ergonomics, and layout—without the need to build a physical prototype.

Tracking Bodies, Hands, and More

A key strength of the BHT CAVE lies in its integration of motion tracking systems. With Advanced Realtime Tracking GmbH & Co. KG motion capture, full-body tracking suits, and MANUS™ Manus VR gloves, users can interact naturally inside the virtual environment. This opens the door to ergonomic studies, immersive training, and behavioral simulations.

“Motion tracking provides significant value,” Wesberg notes. “You can analyze posture, hand interactions, movement in space—it adds another layer to how we study production setups or user experience.”

Different tools serve different needs: Manus gloves allow for intuitive interaction in creative simulations such as game-like escape room scenarios, while technical CAD applications benefit more from the precision of the Flystick controller, ideal for tasks like measuring, object manipulation, or system navigation.

Software Backbone: A Slim, Effective VR Bridge

To make all of this work across various applications, BHT uses moreViz from more3D—a lightweight yet powerful VR bridge that enables real-time visualization of CAD data from software such as Solid Edge, Technomatix, Autodesk, ANSYS, Creo, and others.

Unlike many VR solutions that require complex data conversions or rely on heavy middleware, moreViz runs directly on the native software output. Built-in tools like live measuring, in-VR annotations, and hardware compatibility (including supporting the Manus gloves) make it accessible across a variety of use cases.

“What we appreciate is that it’s not overloaded with features,” Wesberg explains. “It’s efficient, affordable, and works reliably with our tracking systems—including the gloves and motion suits.”

The system also benefits from responsive support: “With more3D, we have a partner who knows the system inside and out and responds quickly when there’s an issue. That’s incredibly valuable.”

BHT has also begun using moreUnity, the Unity integration module from more3D, to bring custom-built simulations into the CAVE—collaborating directly with more3D to optimize performance for their specific environment.

Effort, Maintenance, and Lessons Learned

Installing a VR CAVE is no small feat. It requires detailed planning, hardware configuration, and software integration. But the bigger challenge often begins after installation: operation, maintenance, and onboarding.

“We invest around 10–15 hours per week just in administration, maintenance, and user support,” Wesberg estimates. “And when new staff or lecturers start using the system, you need structured onboarding. A dedicated person or team really makes the difference.” Many teachers need to experience first the benefits of VR/CAVE technology because it requires extra effort for exercises. For this technology to be used, people need to be introduced to it, which significantly increases support.

One valuable lesson: collaboration with institutions that already operate a CAVE can be incredibly helpful—not only for technical knowledge-sharing but also for gathering real-world feedback and avoiding common pitfalls. “If you’re considering such a system, go see one in action and talk to others who run one.”

A Practical VR Tool—Not a Revolution, But a Real Asset

So, has VR transformed teaching at BHT? Not entirely—and that’s the point. The CAVE doesn’t replace physical labs or workshops, but it adds a flexible, scalable layer of experimentation, visualization, and exploration.

It helps students and researchers better understand complex processes in detail, view simulations at real scale, and conduct experiments that would otherwise be too risky, time-consuming, or expensive.

And without moreViz, as Wesberg puts it, “the CAVE wouldn’t make nearly as much sense.” The right software made the system practical, compatible, and worth the effort.

Conclusion: Making Immersion Work

The BHT CAVE represents a smart investment—not in hype, but in usability. By combining reliable hardware, adaptable software, and well-organized staff support, the university has built an immersive system that serves educational and research needs.

The mozzarella experiment may have illustrated the point—but it’s motion tracking, barrier-free design, and cross-departmental collaboration that keep the system running and relevant.

Curious to explore how moreViz could work for your team? We’d be happy to hear from you—just reach out or request your free trial today. Let us know or request your free trial of moreViz.